Self-Diagnostics Alfa Romeo

See also:

Alfa Romeo cars are equipped mainly with Bosch control systems, including: Bosch Motronic ML4.1, 1.7, 2.10.3 / 4, MP3.1, as well as Multec XM and Weber IAF 8F 6V. All Alfa systems control the primary circuit of the ignition system, the fuel injectors and the idling system, the stroke from one unit.

Self-diagnosis function

Engine control systems have a self-diagnostic function that continuously analyzes the signals of the sensors and actuators of the engine and compares them with the reference values. If the diagnostic program detects a mismatch, one or more corresponding fault codes are recorded in the electronic control unit (ECU) memory. Codes will not appear in cases where the defective item is not under the control of the ACM and when a faulty situation is not provided for by its software.

Bosch Motronic ML4.1 and 1.7

In these systems, the BEU generates 4-digit ‘flashing’ codes for manual reading. When extracting these codes with the reader, the numbers displayed on its display can be completely different. At the end of the chapter, codes are given, both with the help of a flashing light bulb, and with the help of a reader. When diagnosing, use the appropriate column of the table, depending on the method of reading.

Other systems

The Alfa-Romeo software does not generate digital trouble codes for systems other than Bosch Motronic ML4.1 and 1.7. The reader reproduces the fault on the screen without accessing the codes. Although the digital code is not available, a malfunction of the system program, if it appears, will be fixed and stored in memory.

The strategy of limited controllability

The Alfa-Romeo system described in this chapter has a mode of limited controllability (a function known as “limp home” or “crash home”). This means that if some malfunctions occur (not all malfunctions cause this mode to be activated), the engine control system is guided not by the sensor readings, but by its reference value. This mode allows the car to reach the garage or service station for inspection and repair, albeit with less efficiency. After troubleshooting, the system returns to normal operation.

Adaptive function

All Alfa-Romeo systems have the ability to adapt, in which the programmed parameter values for some sensors and actuators change during operation, taking into account engine wear for maximum control efficiency.

Fault light

The models for the USA are equipped in accordance with national requirements with a warning light “Check Engine” located in the dashboard, which can also be used to extract trouble codes that can lead to a deterioration in the exhaust composition. market are not equipped with such an alarm system.

Diagnostic Connector Location

Bosch Motronic ML4.1

Two diagnostic connectors are located in the passenger compartment under the dashboard. The 3-pin connector is for connecting the code reader (see figure), and the 4-pin connector is for reading the “flashing” codes.

Bosch Motronic M 1.7

For reading codes in any way, a 3-pin connector is located, usually located under the dashboard on the passenger side next to the BEU.

Other systems

The 3-pin connector is only for connecting the reader. It can be located in the engine compartment on the right wing, either in the center console next to the BEU, or under the dashboard on the driver’s side, or on the passenger side next to the BEU.

Extracting codes without the help of a reader (“flashing” codes)

Note: Additional fault codes may occur during certain checks. Be very careful when checking that these codes do not mislead you. After testing, all fault codes must be erased. The “flashing” codes received without the reader may differ from the codes received with the reader, so when analyzing the codes, refer to the ‘Flashing Codes’ column.

Bosch Motronic ML4.1

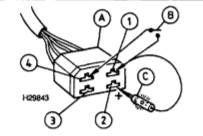

- Connect the LED and auxiliary switch to the 4-pin connector, as shown in Fig.

- Switch on the ignition – the LED should light.

- Close the auxiliary switch for 2.5 … 5.0 seconds, then open it. The LED will light for another 2.5 seconds, then it will start flashing.

- Read the 4-digit codes reproduced by the LED as follows.

- Four numbers are indicated by four series of outbreaks.

- The first series of flashes means the first digit, the second series indicates the second digit, and so on. up to the fourth.

- Each series consists of several flashes lasting 1 or 8 seconds with short gaps between them. The numbers from 1 to 9 are indicated by 1-second flashes, and zero is indicated by a two-second flare.

- One series from the other is separated by a pause of 8.5 seconds.

- Code 1213 is reproduced as follows: one 1-second flash, a short pause, two 1-second flashes, a short pause, one 1 second flash, a short pause, three 1-second flashes. After 8.5 seconds, the code will be repeated.

- Count the number of flashes in the series and write down the code. To decode its value, refer to the table at the end of the article.

- Each code will be repeated until you again close the auxiliary switch for 2.5 … 5.0 seconds, and then open it. After that, the following code will blink. The ML4.1 system can simultaneously

- store in memory no more than 5 codes.

- Continue to extract the codes until code 0000 appears, which means that there are no more codes in the BEU memory.

- If code 4444 appears at once, it means that no fault codes have been registered.

- At the end of the reading procedure, turn off the ignition and disconnect the LED and switch.

Bosch Motronic 1.7

- Ensure that the throttle potentiometer is operational. The procedure described below can not be performed if the BEU does not receive the correct signal from this sensor.

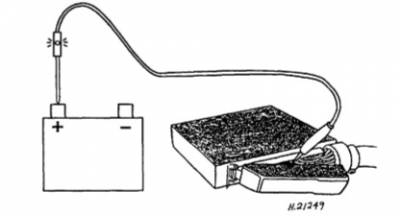

- Connect the LED between the (+) power supply and the pin # 8 of the BEU connector, as shown in Fig. Note. It will be necessary to detach the rear of the ECU connector to get to the correct pin without disconnecting the connector. Be careful – do not damage the connector’s pins and do not short-circuit the two LED contacts.

- Switch on the ignition, but do not start the engine. Five times in a row, fully press and release the accelerator pedal. This process should be completed within 5 seconds after the ignition is turned on.

- The LED will light for 2.5 seconds, then it will start flashing.

- Read the 4-digit codes reproduced by the LED as follows.

a] Four numbers are indicated by four series of flashes.

b] The first series of flashes means the first digit, the second series indicates the second digit, and so on. up to the fourth.

c] Each series consists of several flashes lasting 1 or 8 seconds with short gaps between them. The numbers from 1 to 9 are indicated by 1-second flashes, and zero is indicated by a two-second flare.

d] One series from the other is separated by a pause of 2.5 seconds.

e] Code 1313 is reproduced as follows: one 1-second flash, a short pause, two 1-second flashes, a short pause, one 1-second flash, a short pause, three 1-second flashes. After 8.5 seconds, the code will be repeated.

- Count the number of flashes in the series and write down the code. To decode its value, refer to the table at the end of the chapter.

- Each code will be repeated until you press and release the accelerator pedal 5 times for 5 seconds. After that, the following code will blink.

- Continue to extract the codes until code 0000 or 1000 appears, which means that there are no more codes in the BEU memory.

- If code 4444 appears at once, it means that no fault codes have been registered.

- At the end of the reading procedure, turn off the ignition and disconnect the LED and switch.

All other systems

“Blinking” codes are not provided. It is necessary to use the code reader.

Deleting codes from memory without the help of a reader

Bosch Motronic ML4.1

- To extract the codes, use the procedure described in paragraph 3.

- When code 0000 appears, short-circuit the auxiliary switch for about 10 seconds, then open it. All codes in memory will be erased.

- Turn off the ignition and remove the auxiliary switch.

Bosch Motronic M 1.7

- To extract the codes, use the procedure described in paragraph 3.

- When code 0000 or 1000 appears, fully depress the accelerator pedal for about 10 seconds, then release it. All codes in memory will be erased.

- Turn the ignition off.

All systems [alternative method]

Turn the ignition off and disconnect the negative lead from the battery terminal for about 5 minutes.

Reconnect the wire to the battery. Note. The first drawback of this method is that the BEU will reset all the adapted parameter values to its original state. In order to re-adjust the system to your engine, you need to start the engine cold condition, and then ride the car at different engine speeds 20 … E0 minutes. In addition, it is necessary to let the engine idle for about 10 minutes. The second drawback is that you will have to reset the protective code of the radio, the current time and other stored values, which will also be reset when the battery is disconnected.

Checking actuators without the aid of a reader

Only Bosch Motronic ML4.1

- Connect the LED and auxiliary switch, as shown in Fig.

- Close the auxiliary switch and turn on the ignition.

- Wait 2.5 … 5.0 seconds and open the switch. The LED will show the code 1411 and simultaneously the fuel injection system will be activated. The work of the solenoids of the injectors will be clearly audible.

- And Attention! The nozzles will work as long as the auxiliary switch is open. There is a danger to pour the cylinders with gasoline. Therefore, if you need long (more than 1 second) tests, turn off the fuel pump or remove the fuse.

- Stop the injector check by closing the auxiliary switch.

- After 2.5 … 5.0 seconds, open the switch again. The LED will show the code 1412 and simultaneously activate the idle valve. The operation of the valve solenoid will be heard.

- Stop the valve check by closing the auxiliary switch.

- After 2.5 … 5.0 seconds, open the switch again. The LED will show the code 1413 and the valve timing solenoid will be activated. His work will be clearly audible.

- Stop the solenoid check by closing the auxiliary switch.

- After 2.5 … 5.0 seconds, open the switch again – the LED will show the code 1414 and the charcoal filter purge valve will start. His work will be clearly audible.

- Stop the charcoal filter check by closing the auxiliary switch.

- After 2.5 … 5.0 seconds, open the switch. The LED will show the code 0000, which completes the check of the actuators.

- Turn the ignition off and remove the LED with the switch.

All other systems

A code reader is required to check the actuators.

Self-diagnosis using the code reader

Note. During some checks, additional fault codes may occur. Be careful, do not let the new code down your plans.

All models of Alfa-Romeo

Connect the code reader to the diagnostic socket. Use the reader for the following purposes, strictly observing the manufacturer’s instructions.

a) Extract codes or read information about faults.

b) Deleting codes or fault information,

c) Verification of actuators.

In the systems of Bosch Motronic ML4.1 and 1.7 codes obtained with the reader and using the LED may not coincide. To determine the value of the codes, use the “Code Reader” column in the table at the end of the article.

Codes must be removed after checking the components and after repairing or replacing any component of the engine management system.

Inspection procedures

Ask the BEU for codes or fault information. To do this, use the code reader or the manual extraction procedure described above.

DTCs in the control unit memory

If one or more fault codes are stored in the memory of the control unit, determine the values according to the table at the end of this article.

If several fault codes occur at once, check the common components for them, primarily the grounding and power circuits.

Perform tests in accordance with the recommendations, which describe the tests for most engine management systems.

After troubleshooting, erase its code from memory, start the engine and make sure that the fault does not reappear in all engine operating modes.

Check the codes again. If the codes reappear, repeat the above procedures.

There are no fault codes in the control unit memory

If there is a doubt about the serviceability of the engine and there are no fault codes in the memory of the control unit, the reason is probably that the fault is in a zone not controlled by the engine control system.